PVC pipes fittings Cement

Home » PVC pipes fittings Cement

PVC pipes fittings Cement

PVC pipes fittings Cement

1.Applications

Ideal for bonding and coupling of rigid PVC, UPVC pipes, UPVC, CPVC, PVC.

2.Introductions

PVC P8121 glue adapted to the PVC pipe or PVC sheet medium size which diameter less than 300mm. Applied in civil , industrial PVC piping systems, drinking water, water treatment equipment, industrial piping , golf course, farmland irrigation, ventilation systems and other fields.

3.Useage

Remove all burrs and dirt of square pipe ends. Make sure the entire socket surface is covered. Don’t over coat, especially don’t overcoat thin wall or bell and pipe to avoid pudding inside. Check dry fit of pipe and fitting. Pipe should easily go 1/3 of the way in the pipe bottles, it should be sung. If need tools to coat cement recommended applicators is a natural bristle brush. Apply liberal coat of cement to pipe to the depth of the socket, leave no void. Assemble parts QUICKLY CEMENT MUST BE FLUID. If not fluid ,recoat both parts. Hold pipe an d fitting together for at least 60 seconds and wipe off excess with cloth. Do not pressure test until cement is fully cured. Store in a cool ,dry , well-ventilated place. Please cover the container when not in use.

Orange CPVC pipe glue, cpvc solvent cement

CPVC pipes fittings Cement

PVC Cement Specifications

- Any Colors can be customized

- Curing fast and Environmental friendly

- High solid content

- Very Strong viscosity

PVC pipe adhesive/glue Product Description

PVC pipe adhesive/glue is suitable for bonding PVC pipeline & fittings, PVC Board and other polyvinyl chloride materials in the construction and decoration field. It can be used in sticking the soft and hard PVC products, as well as bonding for PVC and leather, PVC and metal etc.

PVC Cement Properties

1. Any Colors can be customized

2. Heat resistance

3. High solid content and Very Strong viscosity

4. Easy to use, simple operation

5. Environmental friendly and non-toxic

PVC Cement usage Instructions:

— Pipe surface must be clean and dry, no burrs. Single-side or Doulbe-side brush the glue, then bonding immediately(Not after drying). Move or roll the joint to make it tightly.

— The initial adhesive performance could be achieved after drying for 2-3 hours at the room temperature of 25°C. The best adhesive performance is available after drying for 24 hours.

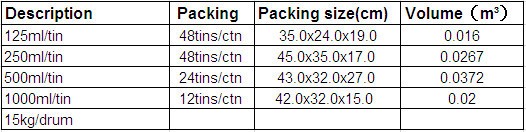

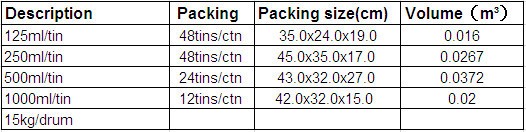

PVC Cement/ glue Packing details

pvc cement packing details